3D Printing and Construction Automation are transforming the construction industry by offering innovative ways to design, build, and manage structures more efficiently, cost-effectively, and sustainably. Here are the key details:

1. 3D Printing in Construction

3D printing in construction involves using large-scale printers to create building components or entire structures. This technology is sometimes called additive manufacturing, as it works by adding material layer by layer to form the object, in contrast to traditional subtractive manufacturing methods.

Key Technologies:

- Concrete 3D Printing (also called concrete extrusion): This is one of the most common types used in construction. A printer deposits a special concrete mix layer by layer to build up walls, foundations, or even entire buildings.

- Material Extrusion: Involves extruding materials like plastics, metals, or composites. This can be used for more decorative elements or specialized structures.

- Binder Jetting: This uses a binding material to bond together layers of powdered material (such as concrete, sand, or metals) to create building components.

Advantages:

- Cost-Effective: 3D printing can significantly reduce labor costs and material waste, making construction more affordable.

- Customization: It allows for complex designs that would be difficult or impossible to achieve with traditional methods.

- Speed: Printing structures can be much faster than traditional methods, reducing the overall construction timeline.

- Sustainability: Less material is wasted in the process, and eco-friendly materials can be used in 3D printing, contributing to greener construction practices.

Challenges:

- Material Limitations: While there are advancements, the range of materials that can be used in 3D printing is still limited compared to traditional construction.

- Regulatory Issues: Building codes and regulations are often not yet fully updated to accommodate 3D printed structures, which can pose a barrier to wider adoption.

Applications:

- Affordable Housing: Companies like ICON and Twente 3D are using 3D printing to create affordable housing solutions in places with high housing demand.

- Disaster Relief: 3D printing can quickly build temporary shelters in areas affected by natural disasters.

- Architectural Features: Custom-made elements such as decorative facades, staircases, and interior components can be 3D printed for aesthetic or functional purposes.

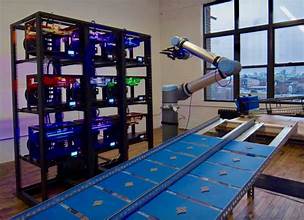

2. Construction Automation

Construction automation refers to the use of automated machines, robotics, and digital technologies to perform tasks traditionally carried out by human workers in the construction industry.

Key Technologies:

- Robotic Bricklaying: Robots like SAM100 (Semi-Automated Mason) can lay bricks with a higher speed and precision than human workers, improving productivity and reducing labor costs.

- Autonomous Construction Vehicles: Machines like excavators, bulldozers, and cranes are increasingly being developed with autonomous capabilities, allowing them to perform tasks without human intervention.

- Drones: Drones are used for surveying and monitoring construction sites, providing real-time data and improving project management efficiency.

- Robotic Construction Arms: These can be programmed to perform specific tasks such as welding, cutting, or assembling pre-fabricated components.

- Building Information Modeling (BIM): BIM is a digital representation of the physical and functional characteristics of a construction project. It’s essential for automation, as it helps integrate various technologies, such as robots and drones, into the construction workflow.

Advantages:

- Increased Efficiency: Automation can drastically reduce construction time by speeding up repetitive or difficult tasks.

- Labor Shortages: Construction automation can help mitigate the effects of labor shortages in the industry by allowing machines to take on tasks that would otherwise require a skilled workforce.

- Improved Safety: Automation can reduce the risks of injuries on construction sites by taking over dangerous tasks.

- Higher Precision: Automated systems are more accurate and consistent than human workers, ensuring better quality control in construction.

Challenges:

- High Initial Investment: Many automated systems and robots require substantial initial investment, making them cost-prohibitive for smaller companies.

- Skilled Labor Transition: Automation can displace workers, requiring a shift in labor skills and education to adapt to new roles in operating and maintaining robotic systems.

- Technical Integration: Ensuring that robots, drones, and machines can work seamlessly together with existing construction processes can be a technical challenge.

Applications:

- Automated Prefabrication: Robots are used to create prefabricated building components in factories, which are then assembled on-site.

- Smart Construction: The use of IoT (Internet of Things) and sensors allows real-time monitoring of a construction site, providing data on material usage, worker performance, and structural integrity.

- Self-Building Houses: Some research projects and companies are developing “self-building” houses where robots can perform all construction tasks autonomously.

Future Trends

- Integration of AI and Machine Learning: As AI becomes more sophisticated, it will play a role in optimizing construction processes, predicting project outcomes, and even creating design solutions.

- Sustainability Focus: New sustainable materials and eco-friendly construction techniques are likely to emerge alongside 3D printing and automation to address environmental challenges.

- Smart Cities and Infrastructure: Automation and 3D printing will be pivotal in developing smart cities, with technologies such as 3D printed roads, bridges, and other infrastructure becoming more common.

Conclusion

3D printing and construction automation are poised to revolutionize the construction industry by improving efficiency, reducing costs, and opening the door for more innovative, sustainable building methods. However, widespread adoption will require overcoming challenges related to technology, regulation, and workforce transition.