ACI 347, “Guide to Formwork for Concrete”, is a comprehensive document developed by the American Concrete Institute (ACI) that provides guidelines and recommendations for the design, construction, and maintenance of formwork used in concrete structures. It is aimed at ensuring safety, efficiency, and quality in concrete formwork practices.

Here are key details of the ACI 347 guide:

Purpose

- The guide aims to provide practical information to professionals involved in concrete construction, including engineers, architects, contractors, and designers.

- It covers the entire process of formwork, from design to execution, maintenance, and removal.

Key Areas Covered

- Formwork Design

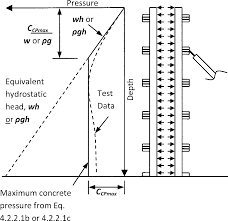

- Structural design principles for formwork, including load considerations, safety factors, and formwork materials.

- Guidelines for determining the required strength and stiffness of formwork to withstand the weight of fresh concrete, construction loads, and other dynamic forces.

- Design considerations for different types of formwork systems such as traditional wood, steel, and modular systems.

- Material Selection

- Recommendations for selecting materials based on cost, durability, and ease of handling. Common materials include wood, plywood, steel, aluminum, and plastic.

- Information on how to assess material performance for specific applications, such as surface finish requirements and resistance to wear and tear.

- Formwork Construction

- Techniques for assembling formwork systems safely and efficiently.

- Best practices for bracing, securing, and shoring the formwork to ensure it can support the concrete load until it sets.

- Safety Considerations

- Emphasis on the importance of safety in formwork construction, including proper worker training, use of protective gear, and maintaining a safe working environment.

- Guidelines for preventing accidents related to formwork collapse, tipping, or overloading.

- Form Removal and Reuse

- Instructions for safely removing formwork after the concrete has set and ensuring the concrete has gained sufficient strength to support its own weight.

- Recommendations on cleaning, storing, and reusing formwork materials for future projects.

- Special Considerations

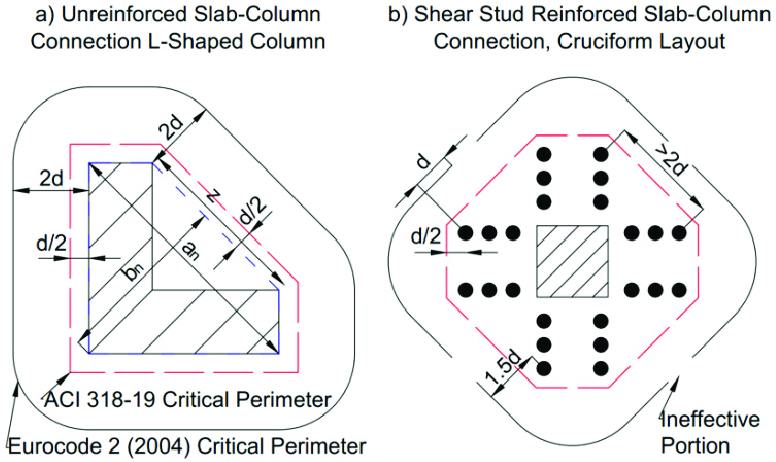

- Details on formwork for complex shapes, curved surfaces, or difficult concrete mixtures.

- Guidance on minimizing formwork defects, such as warping, cracking, or staining, and strategies to achieve a high-quality surface finish.

- Inspection and Quality Control

- Methods for inspecting formwork during construction to ensure compliance with design specifications and safety standards.

- Guidelines for quality control in formwork fabrication, including verifying alignment, levelness, and proper anchoring.

Updates in Recent Editions

ACI 347 has undergone revisions to incorporate the latest practices, materials, and safety standards in formwork construction. Newer editions also emphasize sustainability, efficiency, and cost-effectiveness in formwork design and usage.

Application

This guide is relevant to both new and experienced professionals involved in the construction of buildings, bridges, and other structures requiring concrete. It is particularly useful for large-scale commercial or infrastructure projects that demand precise formwork to ensure structural integrity and durability.