Robotic Construction and Automated Site Operations involve the use of robotics, automation, and digital technologies to perform tasks typically carried out by human workers in the construction industry. These technologies aim to improve efficiency, safety, precision, and reduce costs. Here are some key aspects of robotic construction and automated site operations:

1. Robotic Construction Technologies

- Robotic 3D Printing: Uses large-scale printers to create buildings or components layer by layer using materials such as concrete, metal, or plastics. These robots can create complex shapes and structures that traditional construction methods might find challenging.

- Robotic Bricklaying and Masonry: Robots like Hadrian X can lay bricks autonomously, improving speed and accuracy in building walls. These machines can place bricks, apply mortar, and even finish surfaces with minimal human intervention.

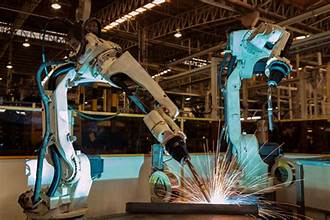

- Robotic Welding and Assembly: Automated welding robots are used for steel frame assembly, providing high precision and consistency in construction of structural components.

- Robotic Demolition: Drones or robots with specialized tools are used to safely demolish buildings, cutting down on the need for human workers to enter hazardous environments.

2. Autonomous Construction Vehicles

- Autonomous Excavators and Bulldozers: These machines are equipped with sensors, GPS, and AI to navigate construction sites without human intervention. They can perform tasks like digging, grading, and transporting materials autonomously.

- Autonomous Material Handling Robots: Robots such as automated forklifts or drones are used to transport materials across the site, reducing the need for human labor and increasing productivity.

3. Construction Drones

- Surveying and Mapping: Drones equipped with high-resolution cameras and LiDAR (Light Detection and Ranging) sensors are used for surveying, creating detailed maps, and performing topographic measurements of construction sites.

- Inspection and Monitoring: Drones are increasingly used for remote inspection of construction sites, inspecting hard-to-reach areas like roofs or towers. They provide real-time data and allow for better monitoring of progress and potential issues.

4. Exoskeletons and Wearable Robotics

- Wearable Devices: Powered exoskeletons are being developed to assist workers with heavy lifting and reduce physical strain. These wearable robotics help prevent injuries and fatigue, allowing workers to perform tasks that would normally require a team.

5. Automated Site Operations and Management

- Building Information Modeling (BIM): BIM is a digital representation of the physical and functional characteristics of a construction project. It integrates with robotics to guide machines through tasks such as material placement and site layout, ensuring consistency with the design.

- AI and Machine Learning: Artificial intelligence helps in project management, from logistics optimization to identifying potential risks and delays. Machine learning algorithms can predict construction timelines and resource needs, aiding decision-making.

6. Safety and Risk Reduction

- Safety Monitoring Systems: AI-based systems can analyze construction site data in real-time to monitor safety, ensuring workers follow safety protocols. These systems can also detect hazardous situations, such as falling objects or machinery malfunctions.

- Robotic Safety Monitors: Some robots are designed to perform safety inspections autonomously, checking equipment, machinery, and structural integrity to prevent accidents and ensuring that safety regulations are followed.

7. Advantages of Robotic Construction

- Increased Efficiency and Productivity: Robots can work 24/7 without the need for breaks, increasing overall productivity and accelerating project timelines.

- Enhanced Precision and Quality: Automated processes reduce the likelihood of human error, leading to higher-quality constructions with fewer defects.

- Cost Reduction: Robotics and automation help reduce labor costs, minimize waste, and streamline construction processes, ultimately lowering overall project costs.

- Improved Safety: Automation removes workers from hazardous tasks and reduces the risk of injuries, leading to safer construction sites.

8. Challenges

- High Initial Investment: Robotic construction technologies often require significant upfront capital for equipment and software development.

- Skilled Workforce: The adoption of automation requires skilled workers to operate and maintain advanced robotic systems.

- Regulations and Standards: Construction is heavily regulated, and implementing robotic technologies requires navigating local laws and standards to ensure compliance.

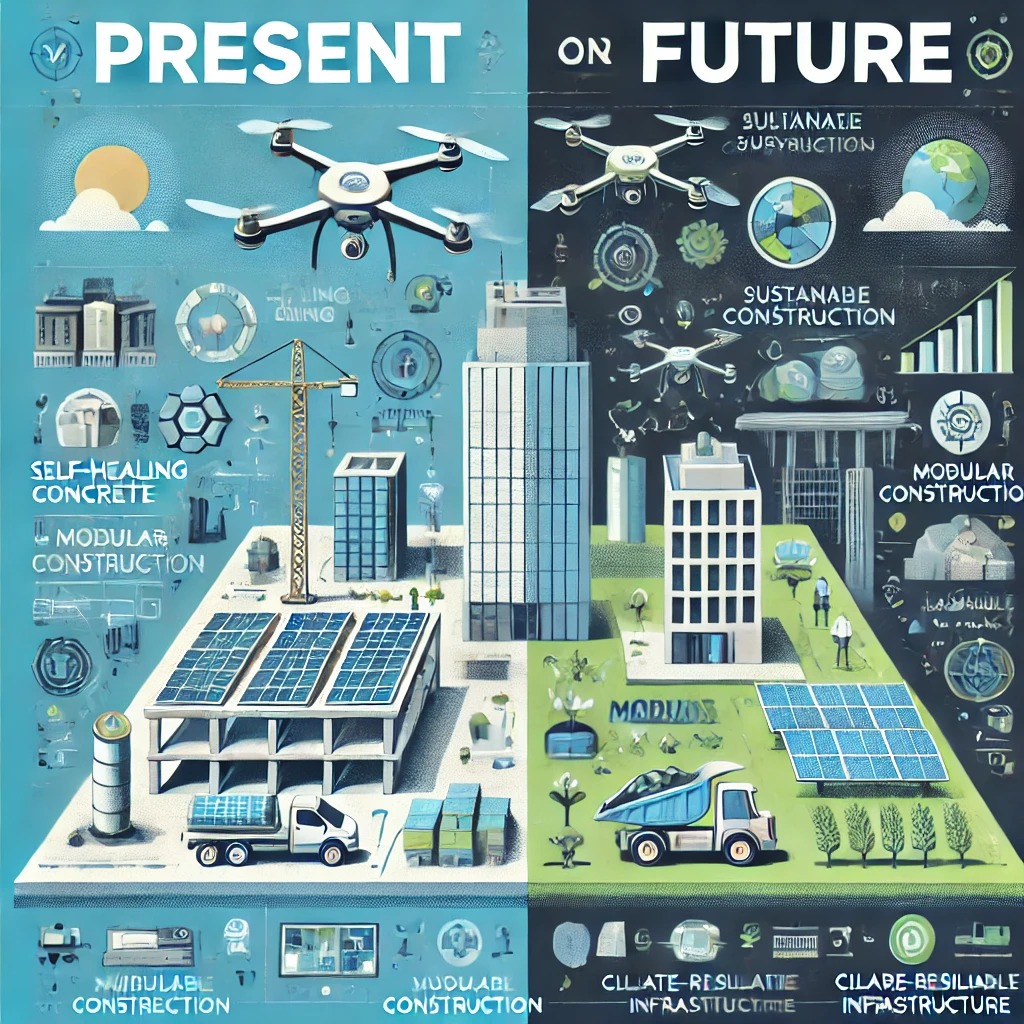

9. Future Trends

- Increased Integration: The integration of robotics with AI, IoT (Internet of Things), and augmented reality (AR) will make construction processes even more efficient, allowing real-time adjustments and dynamic collaboration between machines and humans.

- Sustainability: Robotic construction may contribute to sustainability by optimizing the use of materials, reducing waste, and utilizing sustainable building materials.

- Modular Construction and Prefabrication: Robots will play a key role in assembling modular construction components in controlled environments before transporting them to construction sites.

The ongoing development of these technologies promises to revolutionize the construction industry, making it faster, safer, and more efficient.