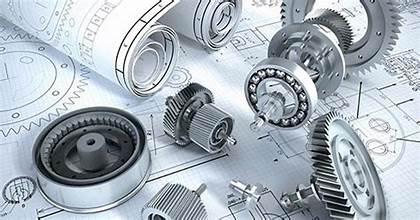

Machinery and Equipment Design is a specialized field of engineering that focuses on creating and developing machines, tools, and mechanical systems for various industries. This discipline blends principles from mechanical engineering, material science, and industrial design to produce functional and efficient equipment that meets specific operational needs.

Key Aspects of Machinery and Equipment Design:

1. Concept Development:

The design process begins with identifying the purpose and requirements of the machine. Engineers collaborate with clients or internal teams to outline performance goals, operational environments, and constraints.

2. Research and Analysis:

Extensive research is conducted to explore existing technologies and materials. This phase may involve studying competitors’ designs, industry standards, and potential innovations to ensure the equipment is cutting-edge and competitive.

3. Design and Drafting:

Engineers use CAD (Computer-Aided Design) software to create detailed blueprints and 3D models. These digital representations allow for virtual simulations and testing, enabling designers to refine components before physical production.

4. Material Selection:

Choosing the right materials is critical to ensure the durability, weight, and cost-effectiveness of the machinery. Factors such as load capacity, heat resistance, and environmental exposure influence these decisions.

5. Prototyping and Testing:

A prototype is developed to evaluate the machine’s functionality and identify potential design flaws. Testing involves applying real-world conditions to verify performance, safety, and efficiency. Adjustments are made based on the outcomes of these tests.

6. Manufacturing and Assembly:

Once the design is finalized, production begins. The machinery is manufactured in parts and assembled according to precise specifications. Quality control measures ensure that the final product meets all design criteria.

7. Maintenance and Upgrades:

Designers often account for long-term maintenance and potential upgrades, ensuring the machinery can be serviced easily. This includes designing modular components and providing detailed operational manuals.

Applications of Machinery and Equipment Design:

- Automotive Industry – Engine components, assembly line robots

- Agriculture – Tractors, irrigation systems, harvesters

- Healthcare – Medical devices, diagnostic machines

- Construction – Cranes, excavators, bulldozers

- Manufacturing – CNC machines, conveyors, production lines

Skills Required:

- Strong analytical and problem-solving abilities

- Proficiency in CAD and simulation software

- Knowledge of materials science and manufacturing processes

- Attention to detail and innovative thinking

Machinery and equipment design is essential for technological advancement, driving innovation across sectors by creating more efficient and reliable mechanical systems.