ACI 301 – Specifications for Structural Concrete is a widely used document that provides comprehensive guidelines for the material and execution requirements of structural concrete. It is published by the American Concrete Institute (ACI) and is frequently referenced in both design and construction of concrete structures. Below is an overview of the key aspects of ACI 301:

1. General Requirements

- Scope: Defines the requirements for materials, workmanship, and quality control procedures for structural concrete.

- Submittals: Specifies the contractor’s responsibilities for submitting mix designs, formwork details, and other documents to the engineer before the start of work.

- Inspection: Includes provisions for the inspection of the concrete construction process, specifying that all work be subject to approval.

2. Materials

- Cementitious Materials: Specifies the types of cement and supplementary cementitious materials (SCMs) that can be used.

- Aggregates: Defines the size, grading, and cleanliness requirements for fine and coarse aggregates used in the concrete mix.

- Admixtures: Details the approved types of admixtures, such as accelerators, retarders, water-reducing agents, and others that can be used in the concrete mix.

- Water: Specifies that water used in concrete must be clean and free of contaminants that could adversely affect concrete properties.

3. Concrete Mix Design

- Strength Requirements: Defines the compressive strength required for the concrete mix at specific ages (typically 28 days) based on the structural demands.

- Mix Proportions: The document requires that the contractor submit concrete mix designs to ensure the mix is appropriate for strength, workability, durability, and other performance properties.

4. Execution Requirements

- Formwork and Shoring: Specifies the design and construction requirements for formwork and shoring, ensuring stability and proper alignment during concrete placement.

- Placing Concrete: Includes procedures for placing concrete to ensure uniformity, including temperature control, compaction, and the avoidance of segregation.

- Curing: Outlines the methods to maintain moisture, temperature, and time required for curing concrete to achieve its desired strength and durability.

5. Finishing and Tolerances

- Surface Finish: Provides specifications for different types of surface finishes, such as rough, smooth, or textured, depending on the intended application.

- Tolerances: Specifies permissible tolerances for various dimensions and geometries of concrete elements (e.g., alignment, plumbness, levelness).

6. Quality Control and Testing

- Concrete Testing: Describes the testing requirements for concrete, including procedures for slump tests, air content, and compressive strength tests.

- Strength Testing: Specifies the method and frequency for taking concrete samples and performing strength tests (e.g., cylinder testing).

- Inspection and Documentation: Details the process for documenting inspection and testing results, and for providing reports to the engineer.

7. Repair and Replacement

- Concrete Defects: Provides procedures for dealing with defects in concrete, such as cracks or honeycombing, and establishes the standards for repair or replacement.

- Acceptance Criteria: Outlines the conditions under which the concrete may be accepted or rejected, including criteria for strength, appearance, and durability.

8. Durability Requirements

- Exposure Classes: Specifies durability requirements based on the exposure conditions, such as freeze-thaw, sulfate attack, or seawater exposure.

- Shrinkage and Cracking: Provides guidelines on controlling shrinkage and cracking, ensuring long-term performance of the concrete.

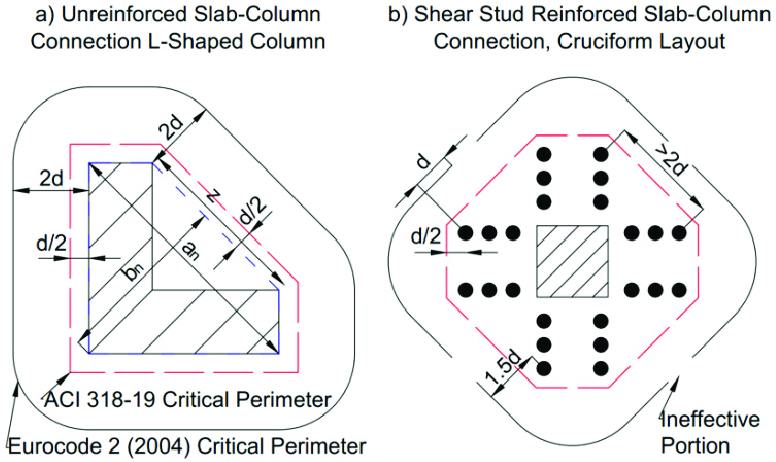

9. Reinforcement

- Reinforcement Placement: Details the proper placement and anchorage of reinforcing steel within the concrete structure, including requirements for cover and positioning.

- Bar Bending and Tieing: Specifies how reinforcement should be bent, tied, and positioned within formwork to ensure structural integrity.

10. Special Requirements

- High-Strength Concrete: Provides guidelines for mixes intended to achieve very high strengths, including handling, curing, and testing procedures specific to such mixes.

- Shotcrete and Precast Concrete: Includes specific requirements for shotcrete (sprayed concrete) and precast concrete elements, which may require different handling and curing techniques.

Conclusion

ACI 301 is a highly detailed and crucial document for anyone involved in the specification, design, and construction of concrete structures. It ensures that concrete is placed, cured, and tested to meet the performance standards needed for safety and durability. Many sections of ACI 301 can be customized or supplemented by project-specific specifications, but the document provides a comprehensive framework for typical concrete construction.