ANSYS is a comprehensive engineering simulation software suite used for product design, testing, and optimization. It enables engineers to model and simulate physical phenomena like structural mechanics, fluid dynamics, thermal analysis, electromagnetic behavior, and more. Here’s a breakdown of key details about ANSYS:

1. Product Overview

ANSYS provides a wide range of simulation tools and capabilities, covering various engineering disciplines. It is used by industries such as aerospace, automotive, energy, electronics, and manufacturing for design and analysis purposes.

2. Key Capabilities

- Structural Simulation: Tools for simulating static and dynamic behavior of structures, including stress, strain, deformation, and vibration.

- CFD (Computational Fluid Dynamics): Used to model fluid flow, heat transfer, and other fluid-based behaviors.

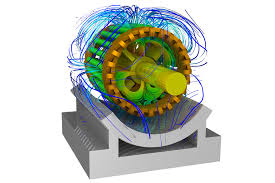

- Electromagnetic Simulation: For analyzing electromagnetic fields, electrical circuits, and their interaction with materials.

- Multiphysics: Allows for the simulation of multiple physical phenomena simultaneously (e.g., thermal, structural, and electromagnetic interactions).

- Optimization: Provides design optimization features for improving performance and reducing costs.

- Additive Manufacturing: Focuses on the simulation of 3D printing processes.

- System Simulation: Enables engineers to model and simulate complex systems and understand their behavior across different components.

3. Applications

- Aerospace: Structural analysis, thermal management, and fluid dynamics simulations.

- Automotive: Vehicle dynamics, crash simulations, and aerodynamics.

- Energy: Wind turbine design, turbine blade analysis, and oil & gas reservoir simulations.

- Electronics: PCB design, thermal analysis, and electromagnetic compatibility (EMC) studies.

- Manufacturing: Process simulations for casting, welding, and machining.

4. Integration with Other Tools

ANSYS can integrate with various CAD and PLM (Product Lifecycle Management) systems, allowing users to import models from platforms like SolidWorks, CATIA, Autodesk, and others. This seamless workflow helps streamline the simulation process.

5. User Interface and Tools

- ANSYS Workbench: A unified environment for setting up, solving, and reviewing simulation results.

- ANSYS Mechanical: For structural simulations, including static, dynamic, and fatigue analysis.

- ANSYS Fluent: A leading CFD solver for fluid flow and heat transfer problems.

- ANSYS Maxwell: Used for electromagnetic simulation, especially for low-frequency simulations.

- ANSYS HFSS: A high-frequency simulation tool for electromagnetic field analysis, commonly used for antenna design.

6. Deployment Options

- On-premise: Traditional installation on local machines or servers.

- Cloud-based: ANSYS offers cloud services for scalable simulation and collaboration, reducing the need for in-house hardware.

7. Licensing and Pricing

ANSYS operates on a subscription-based licensing model. The pricing can vary depending on the type of solution, number of users, and licensing duration. The software is available in different configurations to cater to various industries and simulation needs.

8. Benefits

- Reduces the need for physical prototypes, saving both time and costs.

- Enhances product performance by allowing simulations under realistic conditions.

- Enables early-stage failure predictions and mitigates design risks.

9. Training and Support

ANSYS offers a wide range of resources for learning and training, including online courses, tutorials, webinars, and community forums. It also provides extensive technical support through its customer service team.

Overall, ANSYS is known for its robust simulation capabilities and is widely recognized in the field of engineering simulation.ers and scientists looking to simulate and optimize complex systems in a wide range of disciplines.