DELMIA is a software suite developed by Dassault Systèmes, which specializes in digital manufacturing, factory simulation, and process planning. It is widely used across various industries, including aerospace, automotive, industrial equipment, and consumer goods, for improving production processes and enhancing operational efficiency.

Here are key aspects of DELMIA, especially in the context of aerospace:

1. Digital Manufacturing

DELMIA provides a virtual environment where manufacturers can design, simulate, and optimize their production systems. It allows companies to digitally represent their factory processes, equipment, and workflows, which helps in:

- Reducing time-to-market by testing and refining manufacturing strategies.

- Improving quality by anticipating issues before they arise in the physical world.

- Minimizing costs through the analysis of different production scenarios.

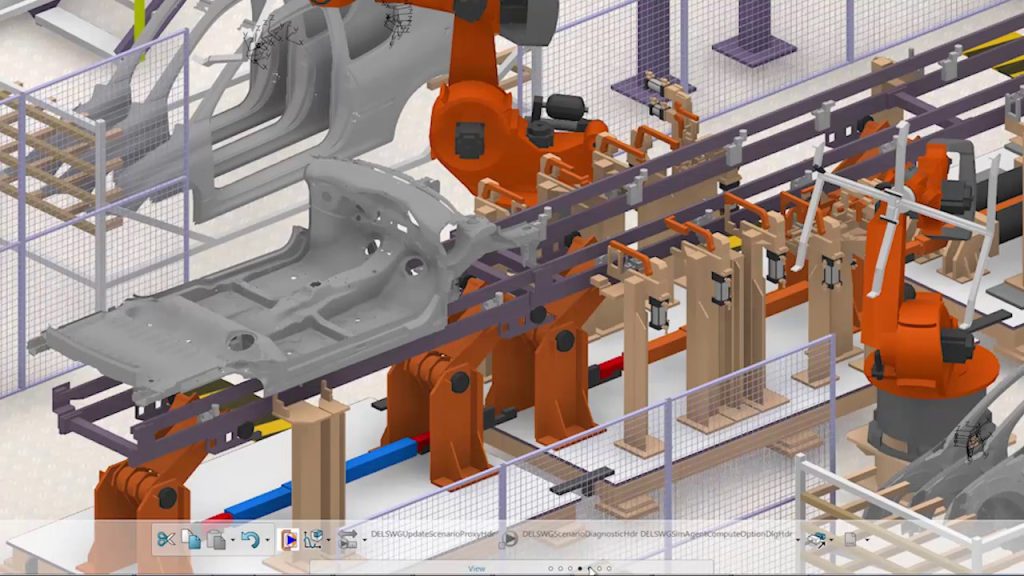

2. Factory Simulation

DELMIA’s factory simulation tools enable the creation of digital twins of manufacturing processes. This includes:

- Simulation of assembly lines: Helps visualize and optimize the layout of production lines, minimizing bottlenecks and inefficiencies.

- Robotics simulation: Simulates robot motions for automated tasks, which is especially beneficial in aerospace for parts handling, assembly, and precision manufacturing.

- Ergonomics studies: Ensures the design of workstations and workflows that maximize worker safety and comfort, which is crucial for high-precision tasks in aerospace.

3. Aerospace-Specific Features

DELMIA has specialized tools tailored to the needs of the aerospace sector:

- Composite manufacturing: Aerospace often uses composite materials, and DELMIA helps design and simulate their production processes.

- Assembly and systems engineering: Aerospace products often involve complex assemblies. DELMIA’s tools help streamline the assembly process, reducing time and cost.

- Lean Manufacturing: Aerospace manufacturers use DELMIA to identify and eliminate waste in their production systems, ensuring that the operations are as efficient as possible.

4. Process Planning and Optimization

DELMIA helps in defining and optimizing manufacturing processes. It enables:

- The creation of detailed process plans for production.

- Simulation of different manufacturing scenarios to optimize material flow and minimize downtime.

- The integration of product design with manufacturing planning, ensuring that designs are manufacturable and cost-effective.

5. Collaboration and Data Sharing

DELMIA is part of the larger Dassault Systèmes suite, which integrates well with other tools, such as CATIA (for product design) and ENOVIA (for product lifecycle management). This ensures:

- Collaborative environment: Teams from different departments (engineering, manufacturing, quality, etc.) can work together seamlessly.

- Data consistency: All teams work with the same version of the product data, reducing errors and miscommunications.

6. Real-Time Analytics and Feedback

The software provides real-time data analysis, which allows manufacturers to make data-driven decisions. In aerospace, this is particularly useful for:

- Monitoring production performance.

- Identifying and addressing inefficiencies in real-time.

- Ensuring that production schedules align with deadlines, particularly for complex, high-stakes aerospace projects.

7. Integration with Industry 4.0

DELMIA is aligned with Industry 4.0, which involves the use of smart, connected technologies in manufacturing. For aerospace, this means:

- IoT (Internet of Things) integration: Sensors and machines are connected, providing real-time insights into machine performance and production processes.

- Advanced robotics: Automation and robotics play a major role in aerospace manufacturing, and DELMIA supports this with simulation tools.

In summary, DELMIA’s digital manufacturing and factory simulation capabilities make it an essential tool for aerospace manufacturers aiming to optimize production, improve quality, and reduce costs while adapting to new technologies and processes in the industry.