Here’s an overview of earthquake-resistant construction techniques using advanced materials:

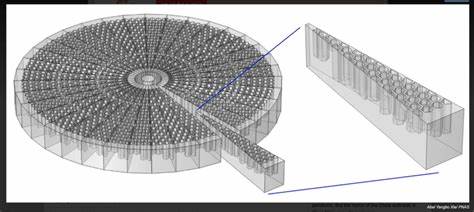

1. Base Isolation Systems

Description: Base isolation involves placing bearings or pads between a building’s foundation and superstructure.

Advanced Materials:

- Lead-Rubber Bearings (LRB) – Combines rubber layers with lead core, allowing flexibility and energy dissipation.

- High-Damping Rubber Bearings (HDRB) – Rubber with additives to enhance energy absorption.

- Friction Pendulum Bearings – Use sliding surfaces with special materials like stainless steel and PTFE (Teflon).

Benefit: Reduces seismic forces transferred to the structure.

2. Seismic Dampers

Description: Dissipate seismic energy to reduce motion.

Advanced Materials:

- Viscoelastic Dampers – Use polymers that deform and absorb energy during earthquakes.

- Fluid Viscous Dampers (FVD) – Use silicone-based fluids to convert kinetic energy to heat.

- Magnetorheological Dampers (MR) – Fluids with magnetic particles change viscosity under electromagnetic fields.

Benefit: Increases damping capacity and prevents structural damage.

3. Shape Memory Alloys (SMA)

Description: Alloys that return to their original shape after deformation.

Material: Nickel-Titanium (Nitinol) alloys.

Application: Used in reinforcement bars, braces, and connectors.

Benefit: High elasticity, self-centering ability, and excellent fatigue resistance.

4. Fiber-Reinforced Polymers (FRP)

Description: Lightweight, high-strength composites for retrofitting and strengthening.

Materials: Carbon fiber, glass fiber, aramid fiber.

Application: Wrapped around columns, beams, and joints to enhance tensile strength.

Benefit: Corrosion-resistant, high durability, and easy to apply to existing structures.

5. Ultra-High-Performance Concrete (UHPC)

Description: A dense, high-strength concrete with superior durability and crack resistance.

Materials: Steel fibers, silica fume, and nano-silica.

Application: Bridge piers, shear walls, and building cores.

Benefit: Withstands extreme forces and minimizes structural damage.

6. Self-Healing Concrete

Description: Concrete that repairs its own cracks through embedded capsules or bacteria.

Materials: Microcapsules filled with epoxy or limestone-producing bacteria.

Application: Foundations, walls, and bridges.

Benefit: Enhances longevity and reduces maintenance.

7. Geopolymer Concrete

Description: Environmentally friendly concrete made from industrial by-products.

Materials: Fly ash, slag, and alkali activators.

Application: Infrastructure, retrofitting.

Benefit: High early strength, reduced carbon footprint, and excellent fire resistance.

8. Flexible Building Materials

Description: Materials that allow controlled deformation under seismic loads.

Materials: Engineered timber (CLT – Cross Laminated Timber), bamboo, and ductile metals.

Application: Modular buildings, low-rise structures.

Benefit: Lightweight, sustainable, and flexible.

9. 3D Printing in Seismic Design

Description: Additive manufacturing of custom structural components.

Materials: High-strength concrete, composite polymers.

Application: Customized joints, structural reinforcements.

Benefit: Rapid, cost-effective, and adaptable designs. evolving challenge, but through research, innovative materials, and thoughtful planning, we can build structures that not only survive extreme weather but also provide long-term sustainability for communities.