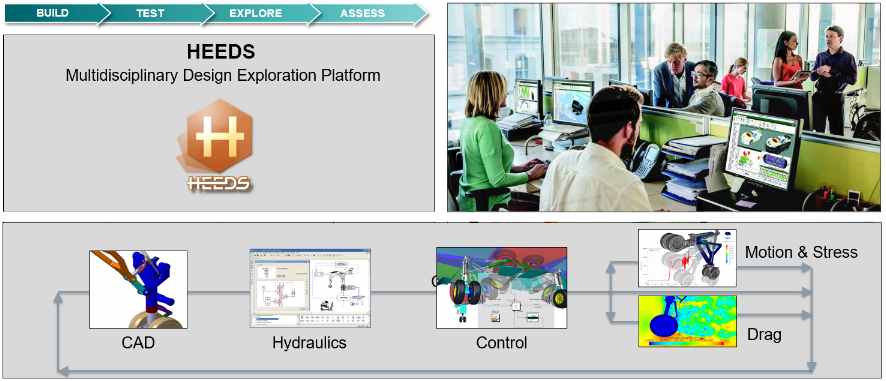

HEEDS (High-performance Engineering Design System) is a comprehensive software platform that supports design space exploration, optimization, and simulation. It is widely used in engineering design for finding the best solutions to complex design problems by exploring the relationship between design variables, performance metrics, and constraints. The software provides a powerful and user-friendly interface for optimizing designs, automating workflows, and analyzing simulation results.

Key Features of HEEDS:

- Design Space Exploration: HEEDS allows users to efficiently explore large design spaces by varying design parameters. It helps identify potential areas of improvement and find optimal solutions in complex systems.

- Multi-Disciplinary Optimization: The software is capable of handling optimization tasks involving multiple disciplines, such as structural, thermal, fluid dynamics, and more. This enables the integration of various simulation tools into a cohesive workflow.

- Surrogate Modeling: HEEDS employs advanced surrogate modeling techniques (like polynomial regression and kriging) to approximate expensive simulations. This allows faster exploration of the design space by reducing the number of required simulation runs.

- Optimization Algorithms: HEEDS integrates several optimization algorithms, including genetic algorithms, gradient-based methods, and other advanced techniques, to optimize the design parameters for the best possible performance while satisfying constraints.

- Parallel and Distributed Computing: HEEDS is capable of running simulations in parallel, either on a local multi-core machine or across distributed computing resources, to speed up the exploration and optimization process.

- Simulation Integration: HEEDS integrates seamlessly with a wide range of third-party simulation tools, including those used for finite element analysis (FEA), computational fluid dynamics (CFD), and other specialized engineering simulations.

- User-Friendly Interface: The software features an intuitive interface for defining optimization problems, visualizing results, and interpreting the outcomes. This makes it accessible for engineers, even those without deep optimization expertise.

- Automated Workflows: HEEDS helps automate the entire design optimization process, including parameter definition, running simulations, analyzing results, and refining designs. This reduces manual effort and ensures consistency.

- Design and Performance Trade-offs: The platform allows for efficient trade-off analysis by visualizing the relationship between design parameters and performance metrics, helping engineers make informed decisions based on multiple objectives.

- Customization and Extensibility: HEEDS provides options to extend and customize its functionality, allowing users to adapt it to specific requirements, including integrating with proprietary tools or implementing custom optimization strategies.

Applications:

- Aerospace: Optimization of aircraft, spacecraft, and propulsion systems.

- Automotive: Design optimization for vehicle components, including crashworthiness, aerodynamics, and powertrain efficiency.

- Energy: Design of renewable energy systems, such as wind turbine blades and solar panels, as well as energy efficiency improvements in systems.

- Manufacturing: Optimizing production processes, tooling designs, and material selection.

Benefits:

- Faster Time-to-Market: By optimizing designs early in the development process, HEEDS helps companies reduce time-to-market and improve product performance.

- Improved Product Performance: HEEDS enables engineers to find better-performing designs by considering a broader range of design variables and constraints.

- Cost Savings: Through optimization, HEEDS helps reduce material waste, energy consumption, and the number of costly physical prototypes.

HEEDS is widely used by engineers in industries such as aerospace, automotive, energy, and manufacturing for its ability to automate complex design processes and find optimal solutions based on performance goals and constraints.