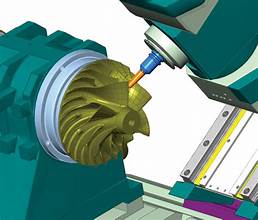

Mastercam is a popular and widely-used CNC programming and machining software. It is known for its versatility and ease of use in various manufacturing industries, including aerospace, automotive, and precision engineering. In the context of aerospace components, Mastercam offers a suite of tools that enable the design and manufacturing of complex parts with high precision and efficiency.

Here are the key aspects of Mastercam that make it suitable for aerospace machining:

1. Advanced Toolpath Generation

Mastercam offers advanced toolpath strategies that are specifically designed to handle the complex geometries and tight tolerances required in aerospace machining. Some key features include:

- 3-axis, 4-axis, and 5-axis machining: Aerospace parts often require multi-axis machining for intricate shapes and contours. Mastercam supports multi-axis operations to ensure accuracy and surface finish.

- Multi-axis toolpaths: These allow for more flexibility in machining aerospace parts, reducing the need for multiple setups, improving part accuracy, and reducing cycle times.

- High-efficiency milling (HEM): For cutting harder aerospace materials, HEM toolpaths optimize the tool engagement and increase material removal rates while preserving tool life.

2. Integration with CAD Software

Mastercam integrates seamlessly with various CAD software packages. This is crucial in the aerospace industry where designs are created in advanced CAD systems like CATIA, Siemens NX, or SolidWorks. Mastercam’s CAD-to-CAM capabilities allow for quick and accurate translation of the CAD model into a toolpath, minimizing errors and ensuring precision.

3. Simulation and Verification

Mastercam includes robust simulation and verification tools that allow operators to simulate toolpaths before actual machining. This is especially important for aerospace components, as they often have complex shapes and materials. The simulation ensures:

- No collisions or toolpath errors

- Verification of the toolpath against the actual part geometry

- Optimization of machine usage and avoidance of tool wear

4. Aerospace Material Support

Aerospace components are typically made from tough, hard materials like titanium, aluminum alloys, and composites. Mastercam offers specialized toolpath strategies to handle these materials effectively. It also provides settings for:

- Optimizing feeds and speeds based on material type

- Tool wear compensation

- Specialized cutting strategies for hard materials like titanium

5. Precision and Tolerance

Mastercam ensures high levels of precision and tight tolerances needed for aerospace applications. Parts like turbine blades, engine components, and structural elements need extreme accuracy, and Mastercam’s advanced toolpath and machining strategies ensure that every part meets the required specifications.

6. Post Processing and Machine Compatibility

Mastercam supports a wide variety of CNC machine brands and models, offering post processors that are customized to specific machines. For aerospace applications, this ensures the right machine tool control codes are generated for the correct machining process. This integration ensures faster setup times, fewer errors, and better machine utilization.

7. Automation and Efficiency

For large-scale aerospace part production, Mastercam offers automation tools to speed up the CNC programming process. These include:

- Customizable macros and scripts for repetitive tasks

- Tool libraries that store cutting tools and parameters for quick access

- Automatic part setup to reduce setup time for multi-part production runs

8. Aerospace Industry Standards

Mastercam is designed to meet industry standards, including those set by:

- AS9100: Aerospace quality management systems

- ISO 9001: Quality management and continuous improvement

- MIL-SPEC: Military specifications for components used in defense and aerospace applications

9. Post-Processing for Additive Manufacturing

Mastercam has extended its capabilities into additive manufacturing, which is gaining popularity in aerospace for creating lightweight and complex parts. This feature is becoming increasingly important for rapid prototyping and customized parts in the aerospace sector.

Summary

Mastercam is a versatile and powerful tool for CNC programming, particularly for aerospace applications. It allows for the creation of high-precision toolpaths, supports advanced machine capabilities, and integrates well with existing CAD systems. Its ability to handle complex geometries, tough materials, and tight tolerances makes it a preferred choice for aerospace component manufacturing.